| Sign In | Join Free | My tjskl.org.cn |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My tjskl.org.cn |

|

Brand Name : AAREAL

Model Number : AY

Certification : ISO9001:2015

Place of Origin : China

MOQ : 1 Set

Price : Negotiable

Payment Terms : T/T, L/C, Western Union, MoneyGram

Supply Ability : 20 sets per month

Delivery Time : 20~30 work days after order confirmed

Packaging Details : Fumigation-free plywood wooden case for export

Model : AY-600, 800, 1000, 1200, 1500, 1800, 2000mm

Screen Decks : 1~5 decks (suggest 1~3 decks)

Screen : stainless steel woven wire mesh, Perforated Plate etc.

Screen Frame : Adhesive type, L type, flange type, ultrasonic type etc.

Mesh Cleaning System : bounce balls, ultrasonic system, rotary brush system etc.

Material : stainless steel 304, 316L, carbon steel etc.

Motion : three-dimensional motion

Application : spice powders, Sugar, Salt, Alkali, starch etc.

Introduction of High Accuracy Industrial Vibrating Sieve Machine for Potato Starch:

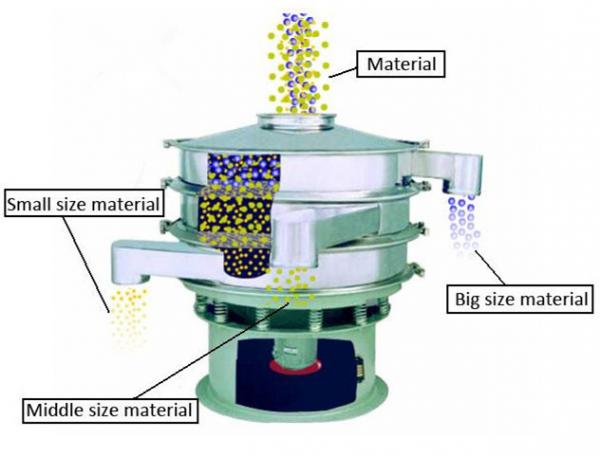

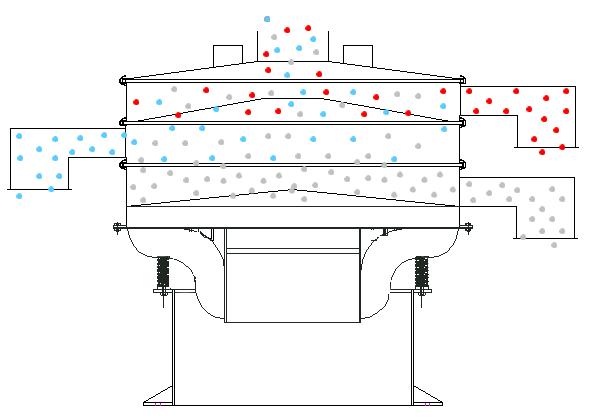

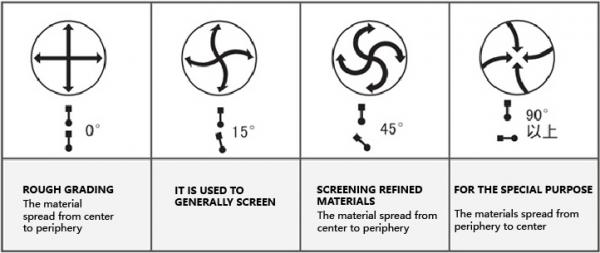

High Accuracy Industrial Vibrating Sieve Machine for Potato Starch is vibratory or gyratory sieving machine designed on the principle of gyratory motion generated by vibro motor. Gyratory motion is the most effective method for screening. Vibro screen are driven by vertically mounted vibratory motor having eccentric weight at the top and bottom end of the shaft. At the time of motor rotation top weight causes vibration in horizontal plane whereas the rotation of bottom weight causes tilt and vibrations in vertical plane. By changing their lead angle, various spiral-screening patterns are obtained to suit different applications. The rotary vibro screen provides optimum screening and assures maximum feed-rate and efficiency. Vibro screen is also known as gyro screen, vibrating screen, vibro sifter, vibro grader, rotary screen, and others.

Our gyro screen machine is more productive compared to conventional round vibro screen separators in terms of increased capacity, accuracy of screening, reduction in noise, loss of good product and production downtime.

Some Information About High Accuracy Industrial Vibrating Sieve Machine for Potato Starch:

| Model | AY |

| Shape | circular or round shape |

| Layers of Screen | 1~5 layers of screen with 2~6 outlets |

| Mesh Size | above 325 mesh |

| Screen Frame | adhesive type, L type (bolt insert type), ultrasonic type (transducer internal and external), flange type etc. |

| Self-cleaning System | bouncing balls (with ball decks), ultrasonic de-blinding system, rotary brush system etc. |

| Diameter | 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm |

| Material | stainless steel 304, 316L, carbon steel, plastic materials etc. |

| Surface Treatment | Paint, sandblast and polish etc. |

| Function | solid-separation, grading, remove the impurity etc. |

| Movement | three dimensional vibration motion |

| Damping Spring | carbon steel spring, stainless steel spring, air spring, rubber spring etc. |

| Motor | one set of vibrating motor, verticle arrangement |

| Motor Brand | AAREAL Made, OLI-WOLONG, Italvibras etc. |

| APO Safety System | Automatic Power Off Safety System is integrated in the motor |

| Quick-wear Parts | mesh screen, perforated plate, bounce balls, clamps, springs, sealing rubber strip etc. |

| Optional Design | discharge gate, magnetic guard, quick release clamp, glass viewing port, collecting tray etc. |

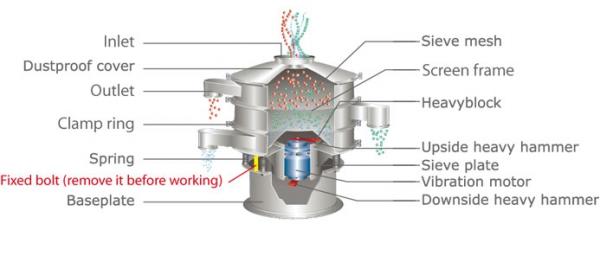

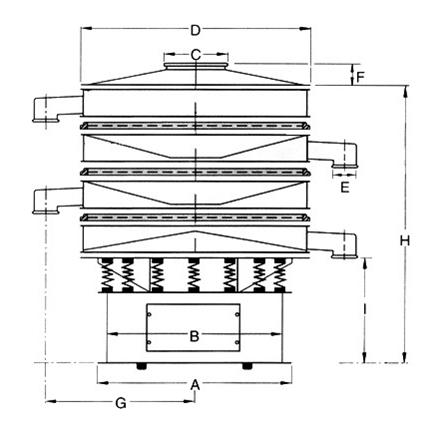

Structure Diagram of High Accuracy Industrial Vibrating Sieve Machine for Potato Starch:

The rotary Vibrating Sifter is composed of a upper cover, a screen box, a base and a vertical motor with eccentric weight installed at two ends. Rotary vibrating screen can be produced in horizontal, vertical, inclined motions by adjusting the upper and lower eccentric weight. Diameter also can be ranged from 400mm to 2000mm, with single or multiple screening decks, material can be total carbon steel, total stainless steel or material contact parts are stainless steel according to different product.

Technical Parameters of High Accuracy Industrial Vibrating Sieve Machine for Potato Starch:

| Model | Power | Screen Surface Diameter | Effective Screening Area (m2) | Layers of Screen |

| AY-400 | 0.18 KW | 350mm | 0.0962 | 1~3 |

| AY-600 | 0.25 KW | 550mm | 0.2375 | 1~3 |

| AY-800 | 0.55 KW | 750mm | 0.4416 | 1~3 |

| AY-1000 | 0.75 KW | 920mm | 0.6644 | 1~3 |

| AY-1200 | 1.1 KW | 1120mm | 0.9847 | 1~3 |

| AY-1500 | 1.5 KW | 1420mm | 1.5829 | 1~3 |

| AY-1800 | 2.2 KW | 1720mm | 2.3223 | 1~3 |

| AY-2000 | 3.0 KW | 1920mm | 2.89 | 1~3 |

Features of High Accuracy Industrial Vibrating Sieve Machine for Potato Starch:

1. Effective for dry or wet applications

2. Absolute control of material movement on the gyro screen surface

3. Available with a painted or stainless steel base

4. Up to five predetermined product fractions in a single operation

Working Principle of High Accuracy Industrial Vibrating Sieve Machine for Potato Starch:

The rotary vibro screening machine is made up of an upright motor as an excitation source. The upper and lower ends of the motor are equipped with an eccentric weight to convert the rotary motion of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transmit this motion to the screen surface. Adjusting the phase angle of the upper and lower ends can change the trajectory of the material on the screen surface.

Purpose of High Accuracy Industrial Vibrating Sieve Machine for Potato Starch:

Grading Solid-liquid Separation Remove the Impurity

Application of High Accuracy Industrial Vibrating Sieve Machine for Potato Starch:

1. Food Industry: Ground powders, spice powders, Sugar, Salt, Alkali, sodium glutamate (MSG) Glutamate, Starch,Powdered Milk, Yeast and Fruit Juice.

2. Chemical Industry: Resin, Pigment, Medicine, Grease, Extinction agent, Rubber and plastic.

3. Abrasive, Glass and ceramic Industry: Silicone Sand, Aluminum Oxide, Grinding Abrasive, Glass dust and fire-proof material.

4. Paper making Industry: Coated slurry, black and white liquor, padding fluid, waste liquid and waste water recycling.

5. Mechanical Industry: Casing Sand,Powder metallurgy, Electromagnetism material, Aluminum Powder, Metal Powder and Alloy.

6. Others: Carbon Black, Activated Carbon and pearl.

Overall Dimensions of High Accuracy Industrial Vibrating Sieve Machine for Potato Starch:

| Model | A | B | C | D | E | F | G | I | Single Layer Height | Double Layer Height | Three Layer Height |

| AY-400 | 472 | 372 | 150 | 400 | 110 | 60 | 300 | 270 | 550 | 660 | 770 |

| AY-600 | 570 | 450 | 200 | 600 | 120 | 80 | 380 | 340 | 730 | 865 | 1000 |

| AY-800 | 690 | 570 | 200 | 800 | 130 | 100 | 550 | 340 | 730 | 865 | 1000 |

| AY-1000 | 810 | 690 | 250 | 970 | 150 | 120 | 650 | 400 | 790 | 925 | 1060 |

| AY-1200 | 970 | 850 | 250 | 1170 | 180 | 130 | 760 | 450 | 860 | 1025 | 1190 |

| AY-1500 | 1180 | 1060 | 250 | 1470 | 200 | 140 | 950 | 480 | 985 | 1180 | 1370 |

| AY-1800 | 1480 | 1360 | 350 | 1770 | 220 | 150 | 1110 | 520 | 1030 | 1220 | 1410 |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

|

|

High Accuracy Industrial Vibrating Sieve Machine for Potato Starch Images |